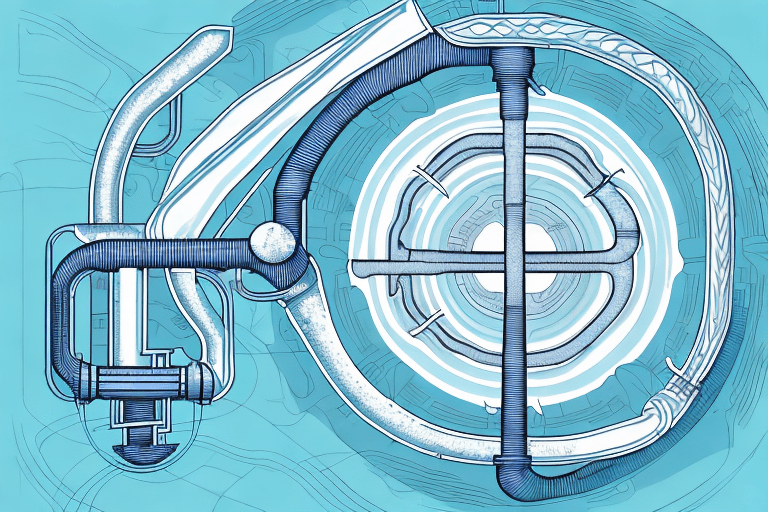

The U-bend, also known as the trap, is a fundamental component of the plumbing system in residential, commercial, and industrial settings. It plays a crucial role in maintaining hygiene and preventing the backflow of gases and waste material. This article will delve into the intricacies of the U-bend, its function, types, installation, maintenance, and common issues.

Understanding the U-bend is essential for anyone involved in the field of plumbing, boiler installs, and gas engineering. It is a simple yet ingenious design that has stood the test of time, proving its worth in countless applications. The following sections will provide an in-depth exploration of the U-bend.

The primary function of the U-bend is to create a water seal that prevents sewer gases from entering a building. These gases, if allowed to infiltrate the premises, can cause unpleasant odors and pose health risks. The U-bend achieves this by holding a small amount of water at all times, which acts as a barrier against the backflow of gases.

Additionally, the U-bend also aids in the smooth flow of waste material. Its curved design allows waste to flow in a controlled manner, reducing the chances of blockages. It also provides an access point for plumbers to clear out any obstructions that may occur.

The water seal is the heart of the U-bend's functionality. It is the body of water that remains in the bend after the fixture has been used. This water acts as a physical barrier, preventing sewer gases from entering the building. The depth of the water seal varies depending on the type and size of the U-bend, but it is typically between 2 to 4 inches.

It is important to note that the water seal can evaporate over time, especially in fixtures that are seldom used. Therefore, it is recommended to periodically run water in such fixtures to maintain the water seal. In certain cases, a trap primer may be installed to automatically replenish the water seal.

The U-bend's curved design plays a crucial role in controlling the flow of waste material. The bend slows down the flow, allowing waste to move in a controlled manner. This reduces the chances of blockages and helps maintain the integrity of the plumbing system.

However, the U-bend is not immune to blockages. Solid waste, hair, grease, and other debris can accumulate in the bend over time, leading to clogs. Regular maintenance and proper usage can help prevent such issues.

While the basic function of all U-bends is the same, there are several types designed for different applications. The type of U-bend used depends on the fixture it is connected to, the plumbing code in the area, and the specific requirements of the installation.

Some common types of U-bends include P-traps, S-traps, and bottle traps. Each of these has its unique design and application, but they all serve the same fundamental purpose of preventing sewer gas backflow and facilitating waste flow.

P-traps are the most common type of U-bend used in residential and commercial plumbing. They are named so because they resemble the letter 'P' when viewed from the side. P-traps are typically used in fixtures that are close to a wall, such as sinks and bathtubs.

The design of the P-trap includes a trap arm and a trap bend. The trap arm connects the trap to the drain line in the wall, while the trap bend creates the water seal. P-traps also often include a cleanout plug, which allows for easy removal of blockages.

S-traps are similar to P-traps, but they are designed for fixtures that are located away from the wall. They are named so because they resemble the letter 'S' when viewed from the side. S-traps are less common than P-traps, as they are more prone to siphoning, which can break the water seal.

Despite their potential issues, S-traps are still used in certain applications where a P-trap cannot be installed. In such cases, special measures are taken to prevent siphoning, such as the installation of a vent pipe.

Bottle traps are a type of U-bend that are commonly used in Europe and other parts of the world. They are named so because of their bottle-like shape. Bottle traps are typically used in fixtures where the trap is visible, such as pedestal sinks, as they have a more aesthetically pleasing design than P-traps or S-traps.

Like other types of U-bends, bottle traps create a water seal to prevent sewer gas backflow. However, they are not as efficient in controlling waste flow, and are therefore not suitable for fixtures that produce a large amount of waste.

The installation of a U-bend is a critical part of the plumbing process. It requires careful planning and precise execution to ensure the proper functioning of the fixture and the overall plumbing system. The installation process varies depending on the type of U-bend and the specific requirements of the installation.

Generally, the U-bend is connected to the fixture's drain and the building's drain line. It is important to ensure that the U-bend is installed at the correct height and angle to maintain the water seal and facilitate waste flow. The installation should also comply with the local plumbing code.

Before installing a U-bend, it is important to plan the installation and prepare the necessary materials. This includes determining the type of U-bend to be used, measuring the distance between the fixture and the drain line, and gathering the necessary tools and materials.

It is also important to consider the local plumbing code, as it may have specific requirements for the installation of U-bends. For example, some codes may require the use of a vent pipe to prevent siphoning, while others may specify the minimum and maximum height for the installation of the U-bend.

The installation process for a U-bend typically involves connecting the trap to the fixture's drain and the building's drain line. This is usually done using slip-joint fittings, which allow for easy adjustment and removal of the trap.

Once the trap is connected, it is important to check for leaks by running water through the fixture. If any leaks are detected, the connections should be tightened or resealed as necessary. After the installation, the trap should be checked periodically for leaks and blockages.

Maintenance is key to the longevity and proper functioning of U-bends. Regular checks and cleaning can prevent blockages and leaks, ensuring that the trap continues to perform its function effectively.

Common maintenance tasks include checking for leaks, cleaning the trap, and replenishing the water seal in seldom-used fixtures. In some cases, it may be necessary to replace the trap, especially if it is old or damaged.

Leaks in a U-bend can lead to water damage and unpleasant odors. Therefore, it is important to regularly check for leaks, especially after the installation or repair of a trap. This can be done by running water through the fixture and checking the connections of the trap for any signs of water leakage.

If a leak is detected, the connections should be tightened or resealed as necessary. In some cases, it may be necessary to replace the trap or its components, especially if they are old or damaged.

Over time, debris such as hair, grease, and solid waste can accumulate in the U-bend, leading to blockages. Regular cleaning can help prevent such issues. This can be done by removing the trap and cleaning it with a brush and warm soapy water.

It is important to note that harsh chemicals should be avoided, as they can damage the trap and the plumbing system. Instead, natural cleaning methods such as baking soda and vinegar can be used. After cleaning, the trap should be rinsed thoroughly and reinstalled.

The water seal in a U-bend can evaporate over time, especially in fixtures that are seldom used. This can break the seal and allow sewer gases to enter the building. Therefore, it is recommended to periodically run water in such fixtures to maintain the water seal.

In certain cases, a trap primer may be installed to automatically replenish the water seal. A trap primer is a device that releases a small amount of water into the trap whenever a nearby fixture is used. This ensures that the water seal is maintained, even in seldom-used fixtures.

Despite their simple design and robust functionality, U-bends can encounter several issues. These include blockages, leaks, siphoning, and evaporation of the water seal. Understanding these issues and how to address them can help maintain the integrity of the plumbing system.

It is important to note that while some issues can be resolved with simple maintenance tasks, others may require the assistance of a professional plumber. Therefore, it is recommended to seek professional help if the issue persists or if you are unsure about how to address it.

Blockages are one of the most common issues with U-bends. They are typically caused by the accumulation of debris such as hair, grease, and solid waste. Blockages can lead to slow drainage, backups, and unpleasant odors.

Regular cleaning can help prevent blockages. If a blockage occurs, it can often be cleared with a plunger or a plumber's snake. If the blockage persists, it may be necessary to remove the trap and clean it manually or replace it.

Leaks in a U-bend can lead to water damage and unpleasant odors. They are typically caused by loose connections, damaged seals, or a cracked or damaged trap. Leaks can often be resolved by tightening the connections or replacing the damaged components.

If a leak persists after these measures, it may be necessary to replace the entire trap. It is recommended to seek professional help if you are unsure about how to address a leak or if the leak persists after your initial efforts to resolve it.

Siphoning is a phenomenon where the water seal in the U-bend is sucked out, allowing sewer gases to enter the building. It is typically caused by a sudden rush of water through the trap, such as when a toilet is flushed or a bathtub is drained.

Siphoning can often be prevented by proper installation and venting of the trap. If siphoning occurs, it may be necessary to adjust the installation or add a vent pipe. It is recommended to seek professional help if you are unsure about how to address siphoning.

The water seal in a U-bend can evaporate over time, especially in fixtures that are seldom used. This can break the seal and allow sewer gases to enter the building. Therefore, it is recommended to periodically run water in such fixtures to maintain the water seal.

In certain cases, a trap primer may be installed to automatically replenish the water seal. A trap primer is a device that releases a small amount of water into the trap whenever a nearby fixture is used. This ensures that the water seal is maintained, even in seldom-used fixtures.

The U-bend is a simple yet ingenious component of the plumbing system. Its primary function is to prevent the backflow of sewer gases into the building, but it also plays a crucial role in controlling the flow of waste material. Understanding the U-bend is essential for anyone involved in the field of plumbing, boiler installs, and gas engineering.

While the U-bend is a robust and reliable component, it can encounter several issues such as blockages, leaks, siphoning, and evaporation of the water seal. Regular maintenance and proper usage can help prevent these issues and ensure the longevity and proper functioning of the U-bend.