The overflow tube is a critical component in plumbing systems, particularly in relation to boiler installs and gas engineering. This article will delve into the intricate details of the overflow tube, its function, design, and the role it plays in the broader context of plumbing systems.

Overflow tubes are typically found in toilet tanks, boilers, and other plumbing fixtures. They serve as a safety mechanism to prevent water from overflowing and causing damage to the surrounding area. This article will provide a comprehensive understanding of the overflow tube, its importance in plumbing, and how it contributes to the efficient functioning of a boiler system.

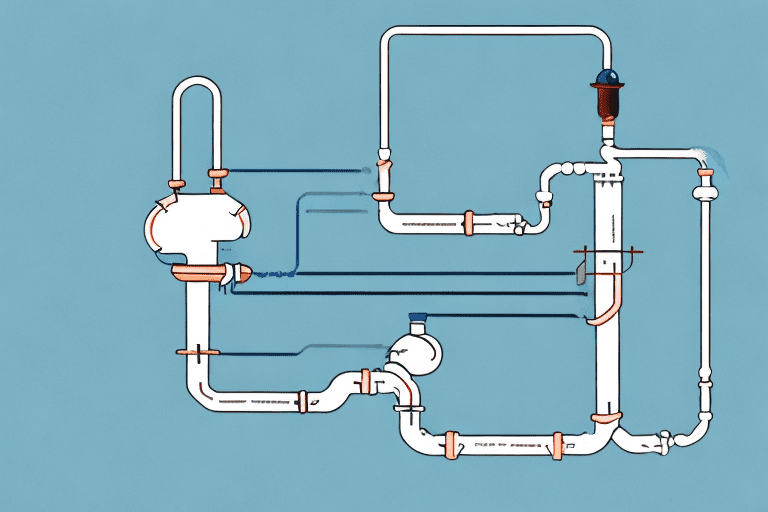

The overflow tube is a vertical pipe that is designed to direct excess water into the drain pipe. It is a crucial part of the plumbing system as it prevents water from spilling over the top of the tank or boiler, which could potentially lead to water damage. The overflow tube is designed to handle the maximum flow rate of the fill valve, ensuring that the water level remains within the safe operating range.

Overflow tubes are typically made of plastic or metal, depending on the specific application and the type of plumbing fixture they are used in. They are designed to be durable and resistant to corrosion, as they are constantly exposed to water and other potentially corrosive substances.

The design and construction of the overflow tube are critical to its function. The tube is typically cylindrical in shape and is designed to fit snugly into the drain hole of the tank or boiler. The top of the overflow tube is usually open, allowing excess water to flow into it and down into the drain pipe. The bottom of the tube is typically connected to the drain pipe, ensuring that the water is directed away from the tank or boiler.

The height of the overflow tube is also an important factor in its design. The tube must be tall enough to prevent water from overflowing the top of the tank or boiler, but not so tall that it impedes the normal operation of the plumbing fixture. The exact height of the overflow tube will depend on the specific design of the plumbing fixture and the maximum water level that it is designed to handle.

The installation of the overflow tube is a critical step in the setup of a plumbing system. The tube must be securely attached to the drain hole of the tank or boiler, ensuring that it is properly aligned and that there are no leaks. The tube must also be properly sealed to prevent water from leaking out around the edges.

The installation process typically involves inserting the overflow tube into the drain hole and securing it with a nut or other fastening device. The tube is then connected to the drain pipe, ensuring that the water is directed away from the tank or boiler. Once the overflow tube is securely installed, the plumbing fixture can be filled with water and tested to ensure that the overflow tube is functioning correctly.

Overflow tubes play a crucial role in boiler systems. They serve as a safety mechanism to prevent the boiler from overflowing, which could potentially lead to water damage and other issues. The overflow tube is designed to handle the maximum flow rate of the boiler, ensuring that the water level remains within the safe operating range.

Boilers are designed to heat water to a certain temperature, and the overflow tube helps to regulate the water level within the boiler. If the water level rises too high, the excess water will flow into the overflow tube and be directed away from the boiler. This helps to prevent the boiler from becoming overfilled and potentially causing damage to the boiler or the surrounding area.

Overflow tubes can also contribute to the efficiency of a boiler system. By preventing the boiler from becoming overfilled, the overflow tube helps to ensure that the boiler is operating at its optimal capacity. An overfilled boiler can lead to inefficiencies in the heating process, as the excess water can dilute the heat and reduce the overall temperature of the water.

Furthermore, an overfilled boiler can also lead to increased energy consumption, as the boiler will need to work harder to heat the excess water. By helping to regulate the water level within the boiler, the overflow tube can help to maintain the efficiency of the boiler system and reduce energy consumption.

The overflow tube is a critical safety feature in a boiler system. If the boiler were to become overfilled, the excess water could potentially cause the boiler to rupture or explode. The overflow tube helps to prevent this by directing the excess water away from the boiler, reducing the risk of a catastrophic failure.

In addition to preventing overfilling, the overflow tube can also help to prevent other potential safety issues. For example, if the boiler were to malfunction and the water level were to rise too high, the overflow tube would help to prevent the water from spilling out onto the floor, which could potentially cause a slip and fall hazard.

Overflow tubes also play a crucial role in gas engineering. They are often used in gas boilers and other gas-powered appliances to prevent water from overflowing and causing damage. The overflow tube is designed to handle the maximum flow rate of the gas appliance, ensuring that the water level remains within the safe operating range.

Gas appliances, like boilers, are designed to heat water to a certain temperature, and the overflow tube helps to regulate the water level within the appliance. If the water level rises too high, the excess water will flow into the overflow tube and be directed away from the appliance. This helps to prevent the appliance from becoming overfilled and potentially causing damage to the appliance or the surrounding area.

Overflow tubes can also contribute to the efficiency of a gas appliance. By preventing the appliance from becoming overfilled, the overflow tube helps to ensure that the appliance is operating at its optimal capacity. An overfilled appliance can lead to inefficiencies in the heating process, as the excess water can dilute the heat and reduce the overall temperature of the water.

Furthermore, an overfilled appliance can also lead to increased energy consumption, as the appliance will need to work harder to heat the excess water. By helping to regulate the water level within the appliance, the overflow tube can help to maintain the efficiency of the appliance and reduce energy consumption.

The overflow tube is a critical safety feature in a gas appliance. If the appliance were to become overfilled, the excess water could potentially cause the appliance to malfunction or even explode. The overflow tube helps to prevent this by directing the excess water away from the appliance, reducing the risk of a catastrophic failure.

In addition to preventing overfilling, the overflow tube can also help to prevent other potential safety issues. For example, if the appliance were to malfunction and the water level were to rise too high, the overflow tube would help to prevent the water from spilling out onto the floor, which could potentially cause a slip and fall hazard.

In conclusion, the overflow tube is a critical component in plumbing systems, particularly in relation to boiler installs and gas engineering. It serves as a safety mechanism to prevent water from overflowing and causing damage, and it also contributes to the efficiency of the system by helping to regulate the water level within the boiler or appliance.

Understanding the function, design, and role of the overflow tube is crucial for anyone involved in plumbing or gas engineering. By ensuring that the overflow tube is properly installed and functioning correctly, you can help to maintain the efficiency and safety of your plumbing system.