The flapper valve, a critical component in the plumbing world, plays a significant role in the operation of various plumbing systems. This article aims to provide a comprehensive understanding of the flapper valve, its function, and its importance in plumbing.

Despite its seemingly simple design, the flapper valve serves a complex function in controlling the flow of water in various systems. Its role in plumbing systems, particularly in boiler installations and gas engineering, is indispensable.

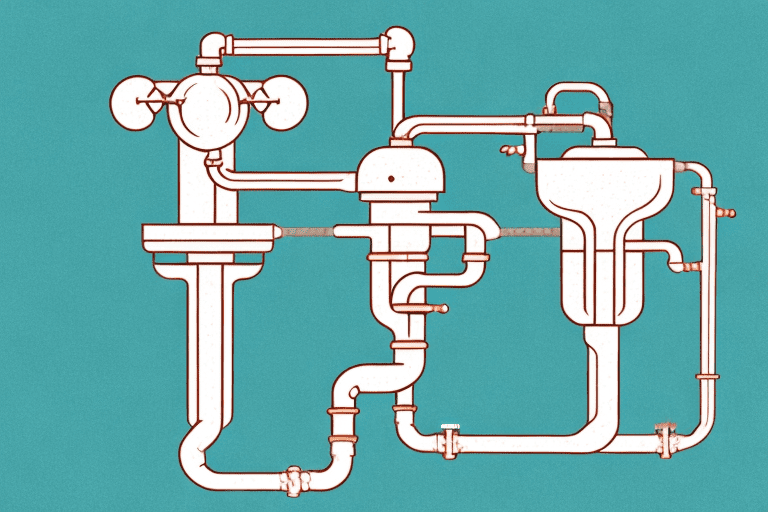

The flapper valve, also known as a check valve, is a type of valve that allows fluid to flow in one direction but closes automatically to prevent flow in the opposite direction. This is crucial in many plumbing systems to prevent backflow or reverse flow of water.

Flapper valves are typically made of rubber and are hinged on one side, allowing them to lift and close with the flow of water. The weight and buoyancy of the valve, combined with the water pressure, control the opening and closing of the valve.

A flapper valve typically consists of the flapper, or disc, and the seat. The flapper is the moving part that opens to allow water flow and closes to prevent backflow. The seat is the fixed part that the flapper rests on when the valve is closed.

The flapper is usually made of a flexible material like rubber, while the seat is typically made of a harder material like metal or plastic. The materials are chosen to ensure a tight seal when the valve is closed and to withstand the pressure and wear of constant use.

There are several types of flapper valves, each designed for a specific application. The most common types include swing check valves, wafer check valves, and stop-check valves. Each type has its unique design and operation principle, but all serve the same basic function of controlling water flow.

Swing check valves have a disc that swings on a hinge or trunnion, wafer check valves have a disc that moves in a straight line, and stop-check valves can be closed manually to stop flow even if there is pressure in the line.

Flapper valves play a crucial role in various plumbing systems, including water supply systems, drainage systems, and especially in boiler installations and gas engineering. They control the direction of water flow, prevent backflow, and protect the system from damage.

In boiler installations, flapper valves are used in the feed water line to prevent the backflow of water into the supply line. In gas engineering, they are used in gas lines to prevent the reverse flow of gas, which could be dangerous.

In boiler installations, flapper valves are used in various places to control the flow of water and prevent backflow. They are typically installed in the feed water line to prevent the backflow of water into the supply line when the boiler is not in operation.

Flapper valves in boiler installations are usually made of metal to withstand the high temperatures and pressures. They are designed to open with the pressure of the feed water and close when the pressure drops, preventing backflow.

In gas engineering, flapper valves are used in gas lines to control the flow of gas and prevent backflow. They are typically installed in the gas supply line to prevent the reverse flow of gas, which could be dangerous.

Flapper valves in gas engineering are usually made of metal to withstand the high pressures and corrosive nature of the gas. They are designed to open with the pressure of the gas and close when the pressure drops, preventing backflow.

Like any other component in a plumbing system, flapper valves require regular maintenance to ensure their proper function. This includes checking for wear and tear, cleaning to remove any debris, and replacing the valve if necessary.

Troubleshooting a flapper valve typically involves checking for leaks, testing the valve's operation, and inspecting the valve for damage. If the valve is not functioning properly, it may need to be replaced.

One of the most common problems with flapper valves is leaking. This can be caused by a worn or damaged flapper, a misaligned seat, or debris preventing the valve from closing properly. Checking for leaks involves inspecting the valve and the surrounding area for signs of water leakage.

If a leak is detected, the cause of the leak should be identified and corrected. This may involve replacing the flapper, realigning the seat, or cleaning the valve to remove debris.

Testing the operation of a flapper valve involves checking the opening and closing of the valve with the flow of water. This can be done by observing the valve during operation or by manually operating the valve.

If the valve does not open and close properly, it may be due to a worn or damaged flapper, a misaligned seat, or a problem with the water pressure. The cause of the problem should be identified and corrected to ensure the proper operation of the valve.

In conclusion, the flapper valve is a critical component in many plumbing systems, including boiler installations and gas engineering. Its role in controlling the flow of water and preventing backflow is crucial to the proper operation of these systems.

Understanding the function and operation of a flapper valve, as well as how to maintain and troubleshoot it, is essential for anyone involved in plumbing. With this knowledge, one can ensure the efficient and safe operation of their plumbing systems.