The vent stack is an integral component of a building's plumbing system. It is designed to remove sewage gases and odors from the plumbing fixtures, such as toilets, sinks, and showers, and release them outside the building. This article will delve into the intricacies of vent stacks, their function, design, installation, and maintenance, and their role in the broader context of plumbing and gas engineering.

Understanding the vent stack and its function is crucial for anyone involved in plumbing, boiler installs, or gas engineering. A well-designed and properly maintained vent stack ensures the efficient operation of the plumbing system, prevents the build-up of harmful gases inside the building, and contributes to the overall health and safety of the building's occupants.

The primary function of the vent stack is to allow the escape of sewer gases from the plumbing system. These gases are produced by the decomposition of organic material in the sewage and can be harmful if inhaled in large quantities. By providing a path for these gases to escape, the vent stack helps to maintain the air quality inside the building.

Another important function of the vent stack is to equalize the air pressure within the plumbing system. This prevents the siphoning of water from the traps in the plumbing fixtures, which could allow sewer gases to enter the building. The vent stack also allows fresh air into the system, which helps to break up waste and facilitate its flow down the drain pipes.

In the context of boiler installs, the vent stack plays a crucial role in the safe and efficient operation of the boiler. It provides a path for the escape of combustion gases, such as carbon monoxide, which can be deadly if allowed to accumulate inside the building. The vent stack also helps to maintain the correct air pressure inside the boiler, which is necessary for the efficient combustion of the fuel.

During the installation of a new boiler, the vent stack must be properly sized and installed to ensure that it can handle the volume of gases produced by the boiler. The vent stack must also be properly sealed to prevent the leakage of gases into the building. Any issues with the vent stack can lead to serious safety risks and should be addressed immediately.

In gas engineering, the vent stack is an essential component of any gas-fired appliance or system. It provides a path for the escape of combustion gases, which can include harmful substances such as carbon monoxide and nitrogen oxides. The vent stack also helps to maintain the correct air-fuel ratio in the combustion process, which is necessary for the efficient operation of the system.

The design and installation of the vent stack in a gas engineering project must take into account a variety of factors, including the type of gas being used, the volume of gases produced, the location of the system, and local building codes and regulations. A poorly designed or installed vent stack can lead to serious safety risks and should be avoided at all costs.

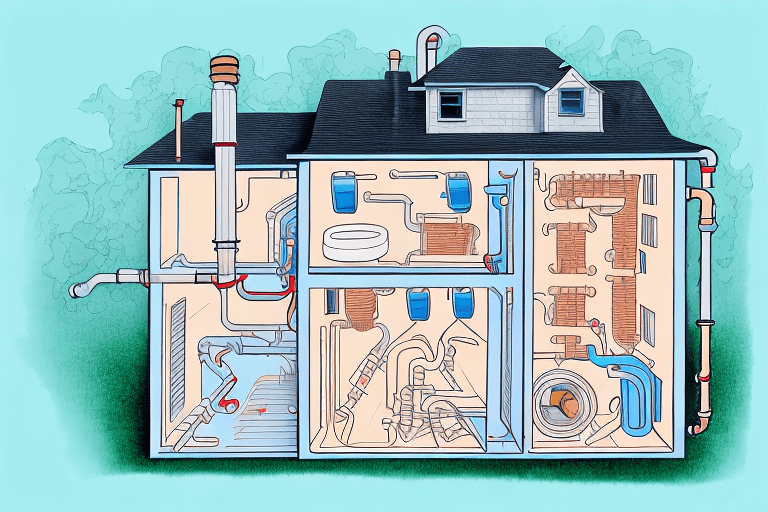

The design of the vent stack is a critical aspect of its function. The size of the vent stack, its material, and its location all play a role in its ability to effectively remove gases from the plumbing system and release them outside the building. The design of the vent stack must also comply with local building codes and regulations, which can vary widely from one jurisdiction to another.

The size of the vent stack is determined by the number and type of plumbing fixtures it serves. A larger vent stack may be required for a building with a large number of fixtures or for fixtures that produce a large volume of sewage. The material of the vent stack is typically PVC, ABS, or cast iron, although other materials may be used depending on the specific requirements of the project.

The location of the vent stack is typically at the highest point of the building, such as the roof, to ensure that the gases are released as far away from the occupants as possible. The vent stack must also be installed in a way that prevents the entry of rain, snow, or other debris, which could block the vent and prevent the escape of gases.

The installation of the vent stack must be done by a qualified professional to ensure that it is properly sealed and secured. Any leaks or loose connections in the vent stack can lead to the escape of gases inside the building, which can be extremely dangerous. The vent stack must also be regularly inspected and maintained to ensure its continued function and safety.

Regular maintenance of the vent stack is crucial for its continued function and safety. This includes regular inspections to check for any signs of damage or wear, such as cracks, leaks, or blockages. Any issues found during these inspections should be addressed immediately to prevent the build-up of gases inside the building.

The vent stack should also be cleaned regularly to remove any build-up of debris or deposits that could block the vent and prevent the escape of gases. This can be done using a variety of methods, including mechanical cleaning with a brush or auger, or chemical cleaning with a specialized vent stack cleaner.

Some of the most common issues with vent stacks include blockages, leaks, and damage from weather or animals. Blockages can be caused by a build-up of debris or deposits, or by the nesting of birds or other animals. These can be cleared using a brush or auger, or by removing the nest or animal.

Leaks in the vent stack can be caused by damage to the vent stack material, such as cracks or holes, or by loose connections. These can be repaired using a variety of methods, depending on the nature and extent of the damage. In some cases, the entire vent stack may need to be replaced.

The vent stack is a vital component of any plumbing system, playing a crucial role in maintaining the air quality inside the building and ensuring the efficient operation of the plumbing fixtures. Understanding the function, design, installation, and maintenance of the vent stack is essential for anyone involved in plumbing, boiler installs, or gas engineering.

With proper design, installation, and maintenance, the vent stack can provide many years of reliable service, contributing to the health and safety of the building's occupants and the efficient operation of the plumbing system. However, any issues with the vent stack should be addressed immediately to prevent the build-up of harmful gases inside the building and ensure the continued function and safety of the system.